HDI PCB for Consumer Electronics: Multilayer PCB Manufacturing at FastTurnPCB (4–50 Layers)

In today’s fast-evolving consumer electronics market, devices are getting smaller, faster, and more powerful. This trend has created an urgent need for high-density, multilayer printed circuit boards (PCBs) capable of supporting complex circuitry and high-speed signals. FastTurn PCB specializes in advanced HDI PCB for consumer electronics, offering multilayer PCB manufacturing from 4 to 50 layers. With their expertise, cutting-edge technology, and strict quality control, FastTurnPCB empowers electronics manufacturers to develop high-performance, reliable devices that meet market demands.

Understanding Multilayer PCBs

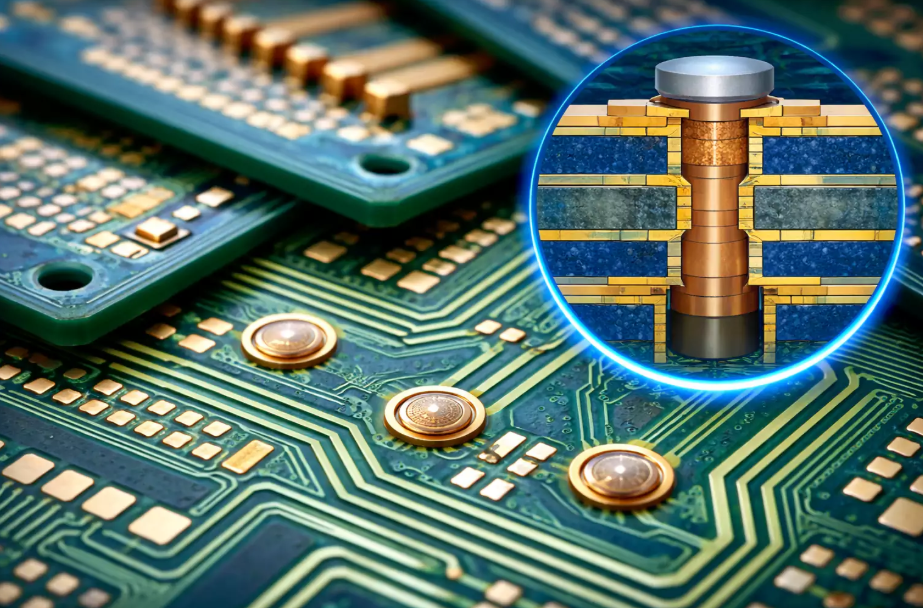

Multilayer PCBs are composed of multiple conductive layers separated by insulating materials and interconnected using vias. These boards allow complex circuitry in a compact form, making them ideal for consumer electronics, where space is at a premium.

FastTurnPCB produces 4–50 layer multilayer PCBs, catering to a wide range of applications, including smartphones, wearables, tablets, and other high-performance consumer devices. Multilayer PCBs provide:

- Increased routing density for complex designs

- Improved signal integrity and electrical performance

- Compact form factors for small devices

- Better thermal management for high-speed components

High-Density Interconnect (HDI) PCBs for Consumer Electronics

HDI PCBs are a key innovation in modern electronics, allowing more connections in less space through microvias, blind/buried vias, and fine-line traces. FastTurnPCB excels in HDI PCB for consumer electronics, offering:

- Microvia technology: Enables high-density connections

- Fine-line routing: Supports high-speed digital signals

- Stackup optimization: Improves electrical and thermal performance

- Support for multiple layers (4–50 layers): Accommodates complex device designs

By leveraging HDI technology, FastTurnPCB helps manufacturers achieve compact, reliable, and high-performance PCBs for next-generation consumer electronics.

Comprehensive Multilayer PCB Services

FastTurnPCB provides complete services for multilayer PCB manufacturing, including design support, fabrication, assembly, and testing.

Design Support and Engineering Consultation

FastTurnPCB offers design-for-manufacturability (DFM) reviews, stackup optimization, and component placement guidance. By collaborating early, manufacturers can ensure their hdi pcb for consumer electronics is manufacturable, reliable, and optimized for performance.

Advanced Fabrication Capabilities

FastTurnPCB’s multilayer PCB fabrication capabilities include:

- Precision etching for fine traces and dense layouts

- Multi-layer stackups from 4 to 50 layers

- Rigid, rigid-flex, and flexible PCB options

- Microvia and buried/blind via drilling

These advanced techniques enable electronics manufacturers to produce compact, high-density boards capable of supporting next-generation consumer electronics.

PCB Assembly Excellence

Assembly quality is critical for high-performance consumer devices. FastTurnPCB offers:

- Surface Mount Technology (SMT) for fine-pitch components

- Ball Grid Array (BGA) assembly with X-ray inspection

- Through-hole and mixed-technology assembly

- High-precision alignment for multilayer HDI boards

By integrating these assembly capabilities with advanced fabrication, FastTurnPCB ensures reliable and durable PCBs for consumer electronics applications.

See also: The Growing Influence of Tech Startups in Global Economies

Rigorous Testing and Quality Assurance

FastTurnPCB implements comprehensive testing protocols to ensure every multilayer PCB meets the highest standards:

- Automated Optical Inspection (AOI): Detects placement and soldering defects

- X-ray Inspection: Verifies microvias, BGAs, and buried connections

- Electrical Testing: Confirms continuity, signal integrity, and functionality

- Functional Testing: Simulates real-world operation to ensure reliability

This thorough approach guarantees that every HDI PCB for consumer electronics performs flawlessly in high-speed, high-density applications.

Rapid Prototyping and Production

FastTurnPCB provides rapid prototyping services to help electronics manufacturers validate and refine their designs quickly. Benefits include:

- Accelerated design iteration and testing

- Reduced time-to-market for new consumer devices

- Early identification of potential design issues

- Smooth transition from prototype to full-scale production

Once prototypes are validated, FastTurnPCB can scale manufacturing efficiently for small or large volumes without compromising quality.

Turnkey PCB Solutions

FastTurnPCB’s turnkey solutions simplify project management by integrating:

- Design support and engineering consultation

- Component sourcing from trusted suppliers

- Fabrication, assembly, and testing

- Logistics and delivery

This comprehensive approach reduces errors, minimizes costs, and ensures that every project is delivered on time and ready for integration.

Supporting Consumer Electronics Manufacturers

FastTurnPCB supports a wide range of consumer electronics projects, including:

- Smartphones and tablets

- Wearables and smart devices

- Gaming consoles and peripherals

- Audio/video equipment

- Smart home devices

By specializing in HDI PCB for consumer electronics, FastTurnPCB enables manufacturers to create compact, high-performance devices that meet the expectations of today’s tech-savvy consumers.

Engineering Collaboration and Support

FastTurnPCB offers engineering support to optimize manufacturability, improve yields, and enhance performance. Services include:

- Reviewing PCB layouts and stackups

- Recommendations for microvia placement and trace routing

- Thermal and signal integrity analysis

- Yield improvement strategies

Early collaboration with FastTurnPCB ensures smoother production and reliable, high-performance consumer electronics products.

Global Reach and Logistics

FastTurnPCB supports electronics manufacturers worldwide, offering:

- Secure international shipping

- Custom packaging for sensitive PCBs

- Inventory management and repeat-order fulfillment

- Full traceability and compliance documentation

This ensures that every multilayer HDI PCB for consumer electronics reaches clients ready for integration into high-performance devices.

Key Advantages of Choosing FastTurnPCB

- Expertise in multilayer HDI PCB for consumer electronics (4–50 layers)

- Advanced SMT and BGA assembly capabilities

- Rapid prototyping and efficient production scaling

- Rigorous testing and quality assurance

- Turnkey solutions from design to delivery

- Global support and logistics

- Cost-effective and scalable manufacturing solutions

These benefits make FastTurnPCB a trusted partner for consumer electronics manufacturers looking to deliver cutting-edge, high-performance devices.

Conclusion

The consumer electronics industry demands compact, high-density, and reliable PCBs. FastTurn PCB provides advanced HDI PCB for consumer electronics, supporting multilayer designs from 4 to 50 layers. Through precision fabrication, rigorous testing, and turnkey services, FastTurnPCB ensures high-performance, reliable, and scalable PCB solutions for modern consumer devices.For electronics manufacturers seeking a dependable partner for multilayer HDI PCB production, visit FastTurn PCB to explore their comprehensive services and capabilities.