Demolition Process for Chemical Plants and Refineries: A Comprehensive Guide

Introduction

Industrial facilities such as chemical plants and refineries are essential to numerous sectors, yet their end-of-life demolition poses significant challenges for safety, the environment, and regulatory compliance. The process entails a series of carefully orchestrated steps involving expert teams, specialized equipment, and robust risk management practices. For a deeper understanding of industry best practices in Chemical Plant Demolition, professionals must recognize the intricate interplay of planning, safety, and sustainability.

Missteps during demolition can result in severe risks to human health, the environment, and local communities. Clear protocols and smart communication make a substantial difference, from the earliest planning discussions to the final site clearance. The following guide outlines essential procedures for safe and efficient dismantling of chemical facilities, spotlighting the strategies and safeguards that should be integral to any project.

Preparation for demolition not only safeguards workers but also helps protect nearby populations and ecosystems, while maximizing asset recovery. By adhering to recognized standards and leveraging advanced demolition technologies, contractors minimize hazards and deliver sustainable outcomes in every project phase.

Facility owners and project leads should remain aware of evolving regulatory environments and technological advances that influence demolition protocols worldwide. Incorporating such insights early can reduce overall project timelines and associated costs.

Pre-Demolition Planning

Successful demolition projects begin with a methodical planning phase. The process typically starts with a comprehensive evaluation of the site to identify hazards, structural vulnerabilities, and opportunities for material salvage. Pre-demolition planning is essential to minimize risks and ensure regulatory compliance. Adequate planning includes the following steps:

- Site Assessment: Structural engineers and project managers perform detailed reviews to locate hazardous materials, unstable structures, and potential sources of contamination. A thorough site survey supports safer design solutions and informs accurate cost projections.

- Regulatory Compliance: Demolition projects must comply with federal, state, and local regulations, such as environmental laws and occupational health requirements. Consultation with governing authorities is critical for permitting, notification, and waste management documentation.

- Stakeholder Communication: Open communication with regulatory authorities, municipal officials, and neighboring communities fosters transparency and trust. Early engagement enables stakeholders to air concerns and expectations, improving project outcomes and minimizing disruptions.

Decontamination Procedures

Decontamination is a critical early stage in plant or refinery demolition. The process involves the targeted removal of residual chemicals and hazardous materials such as asbestos, PCBs, and mercury, which commonly persist in older facilities. Key steps in decontamination include:

- Hazardous Material Removal: Specialized contractors extract, package, and transport hazardous substances for treatment and disposal at licensed facilities. Comprehensive records ensure full traceability and legal compliance.

- Equipment Cleaning: Pipes, storage tanks, and machinery are flushed or chemically cleaned to prevent the release of contaminants during structural demolition. This step is vital for both environmental safety and worker protection.

Industry sources, such as the Environmental Protection Agency, provide further details on federal requirements for handling hazardous waste before demolition. These regulations are designed to protect both workers and the surrounding environment from exposure to toxic materials. Compliance often involves specialized training, proper documentation, and certified disposal methods to ensure safety and legal adherence.

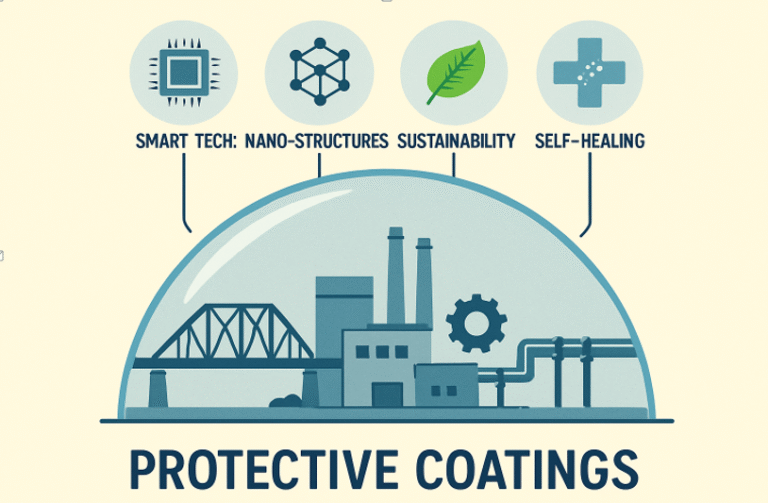

Demolition Techniques

Choice of demolition technique depends on the plant’s structural complexity, proximity to inhabited areas, and desired timelines. The most commonly used methods include:

- Mechanical Demolition: Heavy equipment—such as cranes, excavators, and shears—enables rapid, controlled disassembly of steel frames and concrete structures while limiting worker exposure to hazards.

- Implosion: When appropriate, controlled explosions can bring down large structures with precision. Advanced simulations and strict safety measures ensure minimal risk to adjacent properties and the public.

- Selective Demolition: Some projects require dismantling only specific parts of a facility to allow modifications, site redevelopment, or preservation of critical infrastructure.

Where space and safety allow, a hybrid approach can marry efficiency with environmental care. Detailed engineering studies precede the selection of appropriate methods in all cases.

See also: The Growing Influence of Tech Startups in Global Economies

Waste Management and Recycling

Reducing landfill waste and maximizing material recovery are core goals of modern demolition projects. Effective waste management involves several key practices:

- Material Segregation: Sorting metals, concrete, brick, wood, and hazardous waste types at the source streamlines recycling processes and reduces contamination risks.

- Recycling: Bulk materials such as ferrous/non-ferrous metals, concrete rubble, and even certain plastics are processed for reuse, supporting a circular economy and reducing environmental impact.

Comprehensive materials inventories and logistical plans help demolition teams maximize resource recovery while minimizing costs and waste.

Safety Considerations

Safety is paramount at every stage of the demolition process. Best-in-class projects prioritize worker protection and rapid response capabilities:

- Worker Training: Demolition crews participate in extensive workshops and simulation drills on hazard recognition, equipment operation, and emergency response.

- Protective Equipment: Full-body suits, respiratory protection, and fall arrest systems are mandatory for workers confronting chemical, radiological, or structural risks.

- Emergency Preparedness: Detailed evacuation plans, first-aid stations, and constant monitoring ensure that even unplanned incidents are addressed swiftly and effectively.

Organizations such as the Occupational Safety and Health Administration (OSHA) provide comprehensive resources for demolition project safety. Regular training and safety drills help workers internalize protocols, reducing response times during emergencies. Moreover, integrating technology such as site sensors and wearable devices can further enhance real-time safety oversight and hazard detection.

Environmental Impact Mitigation

Environmental protection is a guiding principle in plant and refinery demolition. Mitigation plans focus on minimizing air, water, and soil pollution:

- Air Quality Control: Water spray systems, negative-pressure containment, and dust capture filters reduce airborne particles and fugitive emissions from demolition work.

- Water Management: Stormwater controls, containment berms, and filtration systems prevent site runoff from carrying contaminants into surrounding water bodies.

- Soil Remediation: Excavation and treatment of affected soils are carried out after demolition to restore site quality for redevelopment or ecological recovery.

Long-term monitoring and adaptive management strategies are often employed to safeguard the site and its surroundings beyond the demolition phase.

Conclusion

Demolishing chemical plants and refineries demands multidisciplinary expertise, adherence to rigorous safety protocols, and a steadfast commitment to environmental stewardship. Stakeholders who invest in robust planning, clear communication, and innovative methods enable successful transitions from legacy facilities to new opportunities, while minimizing risks to people and the planet.